May 27th 2025

|

You already know gases like argon, CO2, and helium are key to a good weld, but what you may not realize is, they could be quietly burning through your budget if you're not careful.

It's not just about saving a few bucks on gas; getting your flow rate right helps keep your welds clean, protects your gear, and keeps your shop running lean and efficient, too.

In this guide, we’ll walk you through some real-world tips on dialing in your gas flow, what variables to watch for, and how to keep things running smoothly.

How to Calculate Gas Flow Rate Accurately

At the end of the day, gas flow rate simply tells you how much shielding gas is moving through your setup over time. The simple formula is:

Gas Flow Rate = Volume ÷ Time

So if you're burning through 240 liters in 20 minutes, you're at a rate of 12 liters per minute (L/min).

A decent gas flow rate calculator measures liters per minute or cubic feet per hour, without making you do the conversions manually.

When you're dealing with changing pressure or temperature in your shop, a digital calculator becomes worth its weight in gold, keeping your numbers spot-on no matter what.

Factors That Will Affect Your Gas Flow Rate

Shielding gas flow isn't one of those "set it and forget it" things. Here's a quick rundown of what you need to keep an eye on:

- Inlet pressure: If your tank pressure is cranked too high, gas is blasting out of your torch faster than you think, even if the flow meter looks steady.

- Temperature: When the shop warms up, that "perfect setting you dialed in earlier? It could suddenly be overkill, causing you to waste gas and compromise your weld.

- Orifice size: A tiny nozzle strangles your flow, no matter what your gauge says.

- Hose length: Those 50-foot hose runs? They bleed pressure at every turn, and if you don't adjust, your weld gets starved without warning.

- Gas density: Argon, CO2, helium- they all flow differently. Switching to a heavier mix and not recalibrating could cause inaccurate flow rates.

- Reynolds number: This invisible number decides whether your gas shields smoothly or turns into turbulent chaos around your weld pool.

- Fluid dynamics: Understanding how gases behave under pressure, friction, velocity, and expansion will keep you from flying blind.

If you don't stay ahead of these variables, your gas flow numbers won’t mean much. You could waste gas, hurt your weld quality, and spend more time fixing problems that never should’ve started.

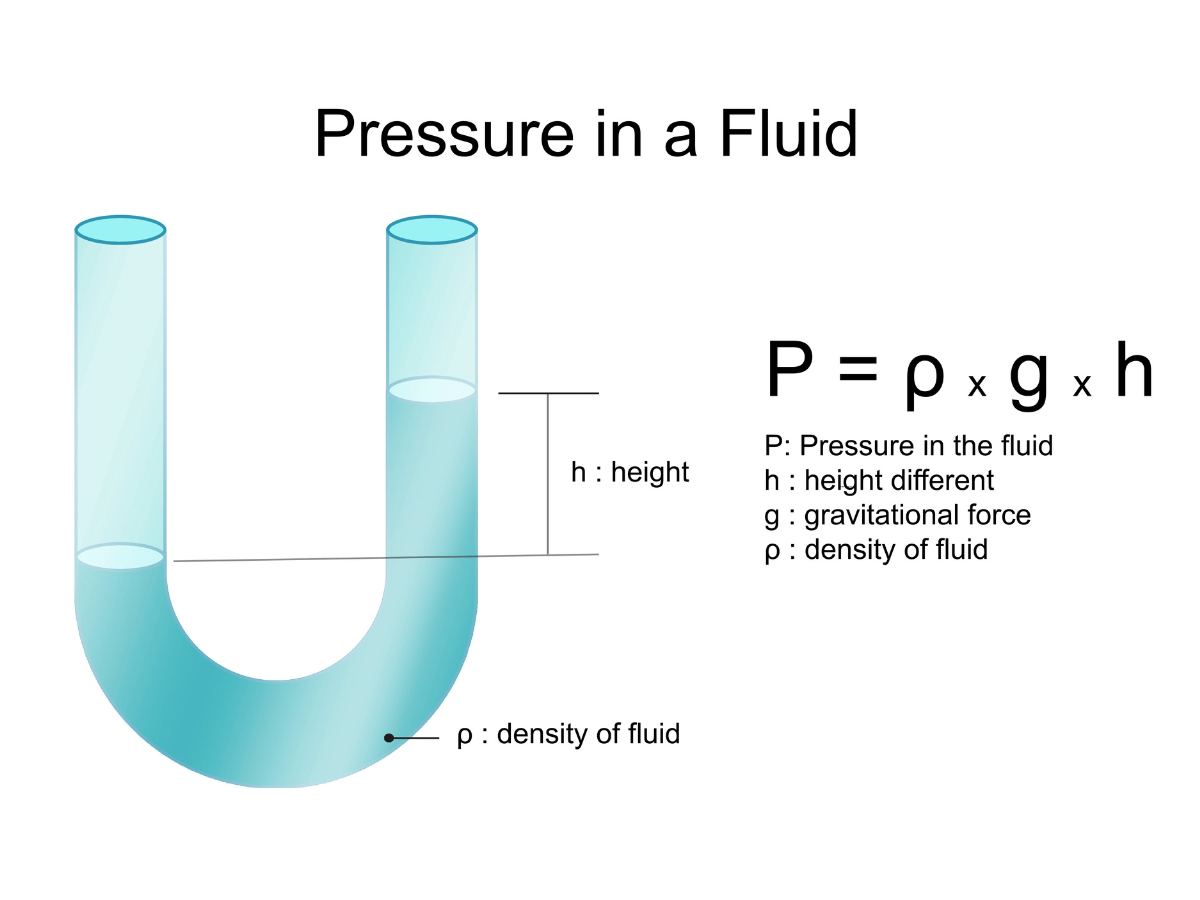

Liquid vs. Gas Flow: Why They're Different

While we're focused mainly on gas flow rate calculators, it’s important to understand how liquid flow plays by a whole different set of rules.

- Liquid is incompressible: It doesn’t squish or stretch much under pressure; it holds its shape and volume.

- Gas expands and contracts like crazy: Even small temperature changes can reduce accurate gas flow readings.

- Different units, different tools: Measuring liquid flow often requires specialized components and different calibration standards.

- Density stays steady for liquids: With gas, density shifts constantly depending on heat and pressure.

If you’re working in systems dealing with both, such as coolant lines and shielding gases, make sure your flow calculator knows the difference. Liquid and gas don't behave the same, and if you don't factor that in, your numbers could end up way off.

The Easiest Way to Calculate Flow Rate

The simplest way to lock in your gas flow is to use a calibrated flow rate calculator designed for welding.

But if you’re determined enough to do it manually:

- Measure exactly how much gas your system pulls; don’t trust settings alone.

- Record the actual time under flow.

- Divide your total volume by total time to find your flow rate and hope nothing shifted midstream.

Manual methods miss a lot; they can’t account for pressure drops, changes in hose diameter, or temperature swings that occur inside your real-world system.

A good digital gas flow rate calculator tracks all of it automatically, giving you numbers you can use to build a weld. It also shows you hidden problems, pressure loss, poor delivery, leaks, long before they wreck your welds.

|

Why Using a Gas Flow Rate Calculator Matters

A good gas flow rate calculator isn’t just about crunching numbers; it's about controlling everything that touches your weld quality and your costs.

Here’s what the right calculator does for you:

- Corrects for standard conditions automatically, so your readings don’t drift when shop temperatures change.

- Accounts for the pressure drop across every hose, fitting, and regulator.

- Handles all your metric-to-imperial conversions.

- Delivers actual mass flow and volumetric flow rate values.

- Supports calculations for pure gases and complex gas mixtures.

- Calculates Reynolds number, so you know if your shielding gas will stay smooth or break into turbulence.

- Adjusts for real-world system parameters, such as hose diameter, width, and flow range.

When your gas flow is dialed in, your welds become tighter, your equipment takes less damage, and your gas supplier sends you smaller bills.

Calculating Total Gas Flow for Job Bidding

Need to figure out how much gas a job will consume? Here's the formula:

Total Gas Used = Mass Flow Rate × Time

Example: You're welding at 18 L/min for 60 minutes: 18 × 60 = 1,080 liters used

Knowing these numbers helps with budgeting, inventory management, and avoiding mid-job gas runs that can reduce productivity.

Many shops track this in gallons or cubic feet, depending on their preferred unit system, while European facilities typically use litres or cubic meters.

Why Mass Flow Rate Beats Volumetric Measurement

Mass flow rate measures the actual quantity of gas molecules being delivered, not just the space they occupy. This distinction matters because:

- Different gases behave differently under the same pressure and temperature

- Accurate billing should be based on mass, not volume

- Gas density changes with pressure and temperature, but mass stays constant

- Incompressible fluids maintain constant density while gases don't

Using the mass flow rate setting on your gas flow calculator gives you the most precise control over your shielding gas management.

Understanding Volumetric Flow Rate and Why It's Tricky

Volumetric flow rate measures the physical space that gas occupies at a specific moment. The problem is that this measurement changes constantly with temperature and pressure.

Good gas flow rate calculators let you input these conditions to get corrected readings that make sense in the real world.

The Reynolds Number: What It Is and Why It Matters

The Reynolds number is a practical tool that predicts whether your gas flow will be smooth (laminar) or chaotic (turbulent). For welders, this number helps determine:

- If gas flows smoothly out of the nozzle

- Whether turbulence might disturb your weld pool

- If your shielding coverage will remain stable during welding

A good gas flow rate calculator should factor in the Reynolds number when recommending optimal flow settings. This parameter becomes crucial for precision work where stable gas coverage can make or break a project.

Making Sense of Nm³/hr in Gas Flow Measurements

Sometimes you'll see gas flow specified in standard cubic meters per hour (Nm³/hr). This standardized measurement assumes gas at standard conditions (0°C and 1 atmosphere of pressure, equivalent to 101.325 kPa or 14.7 psi).

Quick conversion: L/min × 0.06 = Nm³/hr

Example: 50 L/min × 0.06 = 3 Nm³/hr

Any decent gas flow meter should handle these conversions for you. Your tools should make these calculations automatic, saving you from having to memorize conversion factors.

What Happens When the Gas Flow Rate Is Too High

Cranking your gas flow too high isn't just wasteful, it creates turbulence that could:

- Pull air contaminants into your weld pool

- Create porosity and weaken weld integrity

- Waste expensive shielding gas

- Potentially cool the weld pool too quickly

- Result in a higher Reynolds number, indicating turbulent flow

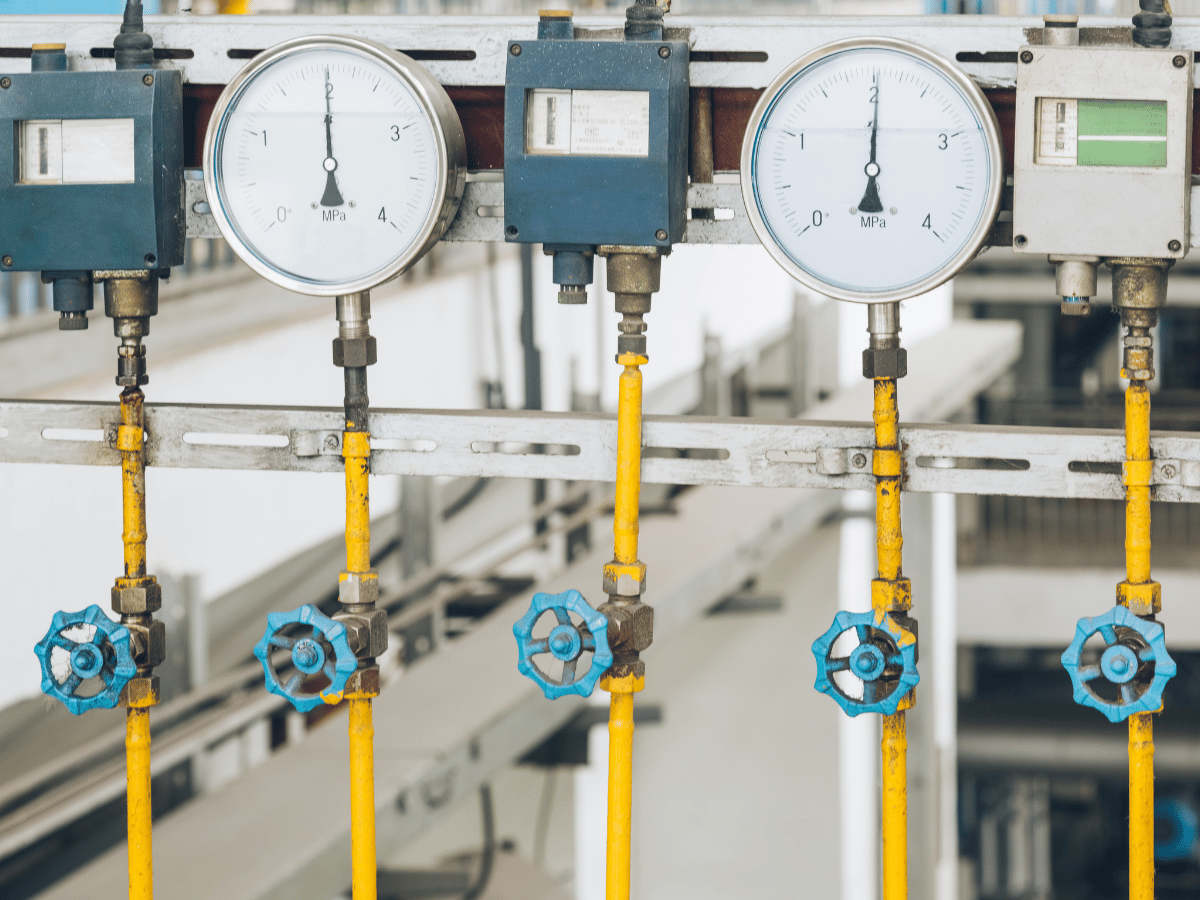

How to Measure Pressure Drop

Pressure drop is the difference between the gas pressure at your tank and what's reaching your torch.

Significant drops usually indicate:

- Leaky connections or hoses

- Restrictions in your delivery system

- Too many fittings or components

- Excessive hose length or insufficient diameter

Factors affecting pressure drop include:

- Hose length and internal diameter

- Number and type of fittings and components

- Gas velocity through the system

- Internal roughness of components

- Pressure levels (measured in psi or bar)

- Gas density and temperature

If you want the most accurate readings, it's a good idea to check in with your equipment manufacturer to see how they recommend calibrating settings.

|

The Truth About Hose Length and Diameter

Hose length and diameter have a massive impact on your actual gas delivery. Every additional 10 feet of hose increases friction and resistance, resulting in lower flow at the torch.

Here's what most welders don't realize: cutting your hose diameter in half increases pressure drop by about 16 times for the same flow rate. That's fundamental fluid dynamics at work.

Keep your gas delivery setup as short and wide as possible, and verify the actual flow using a gas flow rate calculator that takes into account your specific setup.

Mass Flow vs. Volumetric Flow: Know the Difference

Let's break down the key difference:

- Mass flow rate measures the actual number of gas molecules delivered (regardless of pressure, temperature, or volume)

- Volumetric flow rate measures the physical space the gas occupies (which changes constantly)

Mass flow rate uses units like kg/s or lb/min, while volumetric flow rate uses L/min, CFH, or Nm³/h.

In shops with varying conditions, mass flow rate provides a much more reliable tracking of gas consumption. Many modern flow meters now display both measurements so users can choose what's most relevant.

How Temperature Throws Off Your Gas Flow

Shop temperature has a bigger impact on gas flow than most welders realize. As the temperature rises, gas expands significantly, completely changing your adequate coverage.

For every 10°C (18°F) temperature increase:

- Gas volume increases by roughly 3.7%

- Density decreases proportionally

- The mass flow rate stays constant if measured correctly

- Volumetric flow rate requires adjustment

Always correct for temperature changes using a gas flow rate calculator that automatically adjusts readings to standard conditions.

This becomes especially important when working with specialized gas mixture compositions for critical welds where precise shielding is essential.

Converting Between All Those Confusing Units

Common conversions that could be helpful:

- 1 liter = 0.001 cubic meters

- 1 Nm³/hr ≈ 16.67 L/min

- 1 bar = 14.5 psi

- 1 inch = 25.4 mm

Preventing Gas Waste in Your Welding Setup

Tips for ensuring you aren't wasting gas:

- Check all connections, fittings, regulators, and hoses for leaks

- Set proper flow rates for each specific material and torch combo

- Adjust your settings when using longer hose setups

- Use a digital gas flow rate calculator for quick recalibrations

- Monitor actual gas consumption against expected usage

- Maintain all system components properly

- Consider pulse flow technology when appropriate

- Verify your gas mixture ratios are optimized

These practical habits can help slash your shielding gas waste by 20-30%.

Remember, not all TIG welders are created equal. But the right tools elevate outcomes. Monster™ TIG nozzles deliver a coherent stream of shield gas and allow for extended electrode stick-out to

see the zone, get in deep & lay down better welds.

Monster™ TIG welding cups are engineered to deliver a coherent stream of shielding gas allowing a longer tungsten stick-out for improved visibility, weld-quality and consistency. Monster™ nozzles are used by top metal fabricators worldwide!

- Monster10™ Compact and ideal for everyday jobs needing additional gas coverage

- Monster15™ Heavy-duty, large diameter nozzle ideal for pipe and thick plate

- Monster12™ Lightweight, with optimized gas coverage & long stick-out for tight corners

- Monster14™ Compact, versatile and delivers exceptional gas shielding for critical jobs

- Monster16™ Large diameter flooding that delivers umbrella shielding w/out bulk

- Monster24™ Extra Large diameter, specialty flooding for maximum shielding

Why Calibration and Maintenance Matter

Regular calibration of your gas flow rate calculator is essential for accuracy and performance:

- Follow the manufacturer's calibration schedules

- Verify readings against known standards periodically

- Check for component wear that might affect accuracy

- Ensure all pressure and temperature sensors work correctly

- Document your calibration procedures for quality control

Most flow measurement devices require calibration at least once a year, although critical applications may need more frequent verification to maintain accuracy.

|

Conclusion

Shielding gas isn't just pricey, it's a big part of getting clean, solid welds and keeping your shop running smoothly. A good gas flow calculator doesn't just save you cash; it helps you keep things consistent, which helps keep customers coming back.

Dialing in your gas flow with the right tools means better welds, less waste, and a shop reputation people can count on. Gas management is part of what helps keep you sharp in a business where details matter!