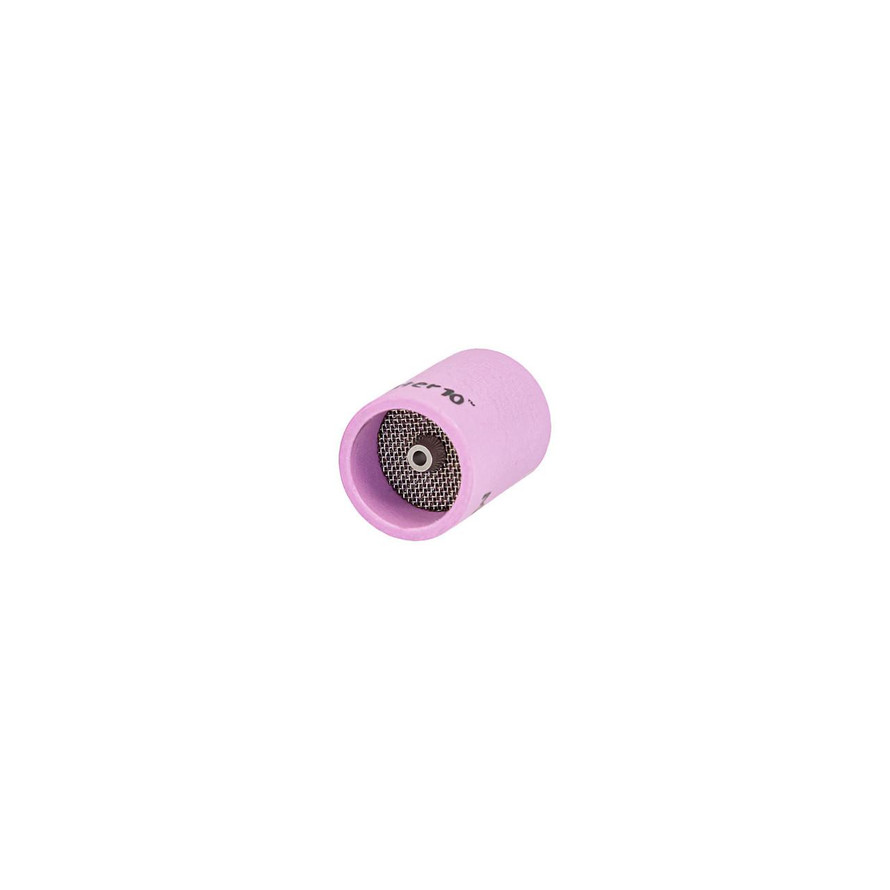

Monster™ Cup w/ Screen Stack - Cup Only -

Monster10™ #10 = 5/8" (15.9mm) Gas Orifice x 1" (25.4mm) Long.

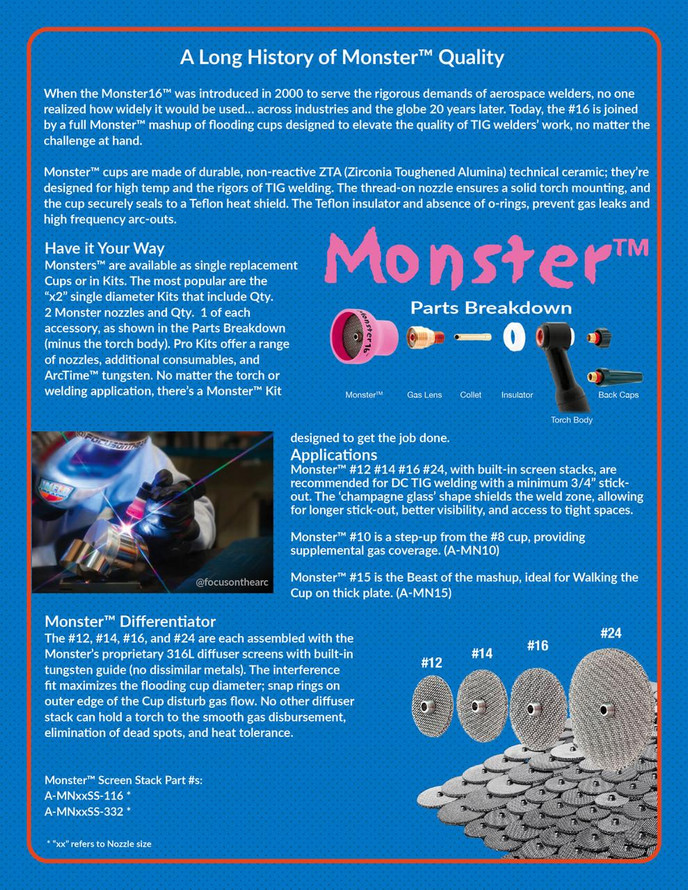

Monster™ TIG welding cups are engineered to deliver a coherent stream of shielding gas allowing a longer tungsten stick-out for improved visibility, weld-quality and consistency. Monster™ nozzles are used by top metal fabricators worldwide!

SAVE Over $10 When You Purchase 2 Cups

Cup Options:

| Part # | Electrode Diameter | Package Quantity |

|---|---|---|

| A-MN10-116 | 1/16" (1.6mm) | 1 |

| A-MN10-116X2 | 1/16" (1.6mm) | 2 (25% Discount) |

| A-MN10-332 | 3/32" (2.4mm) | 1 |

| A-MN10-332X2 | 3/32" (2.4mm) | 2 (25% Discount) |

Monster™ Cup Best Practices, Set-Up Tips, Do's & Don'ts!

- The Monster™ Cup works best with Arc-Zone's high-quality gas lens collet bodies

- The Monster™ Cup is designed for Argon flow rates between 15-30 CFH (cubic feet hour)

- Do Not Exceed 175 amps for extended periods of time!

- The Monster™ Cup is Not designed for welding with AC current!

- Minimum tungsten stickout of 3/4" (19mm) -- Shorter stickout may result in damage to the screen stack

- Use a medium or short back cap ONLY. (Long back caps are known to trap atmosphere in the top of the cap)

- Do not adjust the positioning, or modify the Screen Stack in any way

Monster™ nozzles are designed for precision TIG welding applications where increased shield gas coverage and tungsten stickout are needed. They are not designed for heavy-industrial pipe welding applications.

Arc-Zone does not make any claims or guarantees of weld-quality improvements, or level of shield gas coverage. Results may vary, due to: weld station set-up, material preparation, gas quality, gas flow rates, flow meter type, gas hose material, welding machine, TIG torch, operator’s torch handling technique, etc.

Compatible with most popular TIG torch models.

Have a question? ask our team

(0) Reviews

(0) Reviews

There are no reviews associated with this product.

Write a Review