Cyclone 212

The Cyclone 212 is a ruggedly built, high-performance MIG and Stick welder that delivers exceptional power and capability in a compact, space-saving design. Thanks to its advanced digital IGBT inverter technology, the Cyclone 212 can provide up to 230 amps of MIG output while supporting either 8" (10-12 lb) or 4" (2 lb) spools of wire. For Stick welding, it offers a solid 160A output at a 35% duty cycle, handling most 5/32" 70XX welding rods with ease.

Despite its compact and sleek design, the Cyclone 212 doesn’t compromise on performance. The welder is built for portability with a space-efficient case, and its front, rear, and middle carrying handles make it easy to transport. This, along with its dual 120/240V operating capability, makes it perfect for both shop and on-site jobs.

Everlast has taken the Cyclone 212’s design to the next level by simplifying the internal components with a fully digital setup. The result is a more reliable, modular, and easier-to-repair welder. This digital control not only reduces the number of components, but it also increases the overall lifespan of the unit. The Cyclone 212 comes with a 5-year warranty, ensuring long-lasting durability.

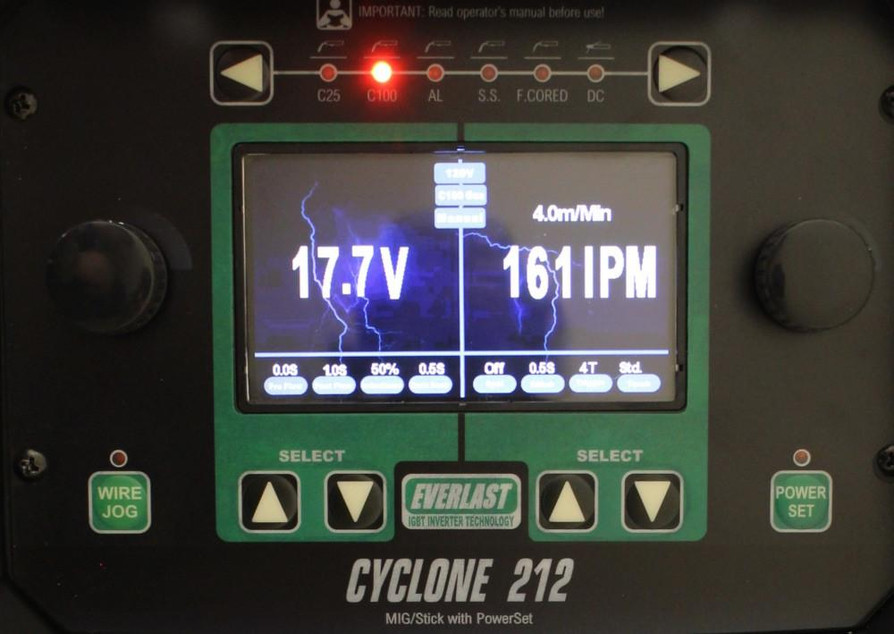

The Cyclone 212’s intuitive digital display and PowerSet function are designed to make setup simple and error-free. When plugged in, the machine analyzes the input voltage, adjusts the output, and provides a voltage reminder. The display also gives an animated depiction of the correct polarity, which is crucial when switching between MIG and Flux-Cored welding. For those new to welding or those who want a quick setup, the PowerSet function provides the best starting parameters based on wire thickness, metal type, and plate thickness. For more experienced users, the unit also offers full manual mode with adjustable settings like spot weld time, inductance, and burn-back, while synergic mode presets these for convenience.

With a 35% duty cycle at 200 amps and a max output of 230 amps, the Cyclone 212 competes strongly in the 200A MIG market. Its intuitive digital display, ease of setup, and affordable price point make it a standout choice for both hobbyists and professionals. The large color display is designed to be easily visible even in bright light, and the PowerSet function ensures quick and accurate settings.

The Cyclone 212 also offers flexibility for aluminum welding between 1/8" and 1/4" thick. It can be used with the optional SM200N-MTS spool gun or, for a more budget-friendly option, with a standard MIG gun by simply changing the liner and drive rolls.

When compared to other welders on the market, the Cyclone 212 offers unparalleled features, performance, and value. Backed by Everlast's 5-year parts and labor warranty, this unit is a game-changer in the MIG welder category, setting a new standard for performance and reliability.

Features:

- 230A MIG output, 160A Stick Output

- 600 IPM Wire feed speed 240V

- 400 IPM Wire feed speed 120V

- 4.3" TFT Digital Color Display

- New advanced version of PowerSet (Synergic) Function for MIG and Stick

- Dual Voltage 120/240V

- Digital IGBT Inverter design offers stable, low spatter arc performance

- Arc force control (Inductance) adjusts arc characteristics in both MIG and Stick modes

- Spot Timer

- Inductance for MIG

- Hot Start and Arc Force Control for Stick

- Burn Back Control

- 24 series MIG Gun with 10 ft. (3m) cable designed with comfort in mind (Binzel/Trafimet compatible)

- Eurostyle quick coupler allows easy aftermarket changeover to other MIG Guns

- Weld aluminum with optional Spool Gun or with MIG Gun with optional Polymer Liner and U-Groove Drive Rolls

- Heavy Duty cast aluminum wire feed assembly with positive gear driven rollers

- Over current and duty cycle features both warning message and weld interrupt

- Polarity Reminder

- Pre and Post Flow Control

- Adjustable Burn back control

- Truly portable "suitcase" size and light weight

- .030-.035" V-Groove and Serrated groove (Flux-Cored) Stock drive roll size

Comes Complete With:

- 24 series MIG Gun with 10 ft. cable and Euro style quick connector

- Stick Electrode Holder with 10 ft. cable and 35 DINSE connector

- Ground Clamp with 10 ft. cable and 35 DINSE connector

- Ar/CO2 Regulator with Hose

- Drive Roll V Groove .030"-.035" (Single)

- PigTail Adapter 110V/220V

- Welding Repair

- Automotive/Muffler shops

- Motorsports

- Construction

- Fabrication

- HVAC

- Factory maintenance

-

Type

Digital/Micro-controlled IGBT Inverter -

Output/Process Type

MIG, Stick -

Voltage/Phase

DUAL VOLTAGE 120/240 1 PHASE -

Max Rated MIG Amps

@ 120V: 125A -

Max Rated MIG Amps

@ 240V: 230A -

Max Rated Stick Amps

@120V: 100A -

Max Rated Stick Amps

@240V: 160A -

MIG Amps/Volts @ Rated Duty Cycle

@120V: 125A/20.25V @ 35% Duty Cycle @ 40°C -

MIG Amps/Volts @ Rated Duty Cycle

@240V: 230A/25.5V @ 15% Duty Cycle @ 40°C -

MIG Amps/Volts @ Rated Duty Cycle

@240V: 200A/24V @ 35% Duty Cycle @ 40°C -

MIG Amps/Volts @ Rated Duty Cycle

@240V: 160A/22V @ 60% Duty Cycle @ 40°C -

Stick Amps/Volts @ Rated Duty Cycle

@ 120V: 100A/24V @ 35% Duty Cycle @ 40°C -

Stick Amps/Volts @ Rated Duty Cycle

@240V: 160A/26.4V @ 35% Duty Cycle @ 40°C -

Stick Amps/Volts @ Rated Duty Cycle

@ 240V: 130A/25.2V @ 60% Duty Cycle @ 40°C -

Max Inrush (I1MAX) Amps

@120V: 33A // @ 240V: 40A -

Maximum Rated (I1EFF) Input Amps

@120V: 20A // @240V: 20A -

OCV

MIG: 60V // Stick: 60V -

MIG Output Range

@120V: 30-125A; 15.5V-20.25V -

MIG Output Range

@ 240V: 30-230A; 15.5V-25.5V -

Stick Output Range

@120V: 10-100A; 20.4V-24V -

Stick Output Range

@240V: 10-160A: 20.4V-26.4V -

Variable MIG Inductance/Stick Arc Force Control

Yes -

Spool Gun Capable

Yes -

Pulse

No -

Separate Wire Feeder

No, self contained -

Number of Drive Rollers

2 -

Max Wire Feed Speed

@120V: 400IPM // @240V: 600IPM -

Max Wire Roll Diameter

8” (up to 12 lb) -

Memory

No -

Preflow Time

1-10 Seconds, or Auto -

Post Flow Time

0-10 Seconds, or Auto -

Flux Core

Yes, Optional -

2T/4T /Torch latch/Trigger

Yes -

Torch Type

MIG: 15 Series -

Other Features

Standard Drive Roll Size: V groove and Flux Cored .030"-.035" (Others optional) -

Other Features

MIG Spot Time: 0-15 Seconds -

Other Features

MIG Stitch Time: 0-15 Seconds -

Other Features

MIG Burn Back Time: 0-2 Seconds -

Other Features

Stick Arc Force: 0-100% -

Other Features

Stick Hot Start Time: 0-2 Seconds -

Other Features

Stick Hot Start Intensity: 0-100% over set Amperage (based on Amp availability) -

Weight

56 Lbs -

Dimensions (LxWxH)

25 in x 9.5 in x 15 in

Have a question? ask our team

(0) Reviews

(0) Reviews

There are no reviews associated with this product.

Write a Review