Jun 25th 2025

Proficient welders will have the basics down, a decent machine, a torch, and enough skill to lay a solid bead. However, great welders know that the right accessories often make all the difference in taking your welding to the next level.

It doesn’t matter how good you are if your gear isn't dialed in and your welds will show it. If your gas coverage is subpar or your tungsten keeps wandering, you're fighting an uphill battle in welding shops where quality matters, such as manufacturing, aerospace, and construction. There is no room for inconsistent welds or contaminated joints, especially in these types of industries.

The good news? You don't need to buy a whole new welding setup to improve your welding skills. Just upgrading a few key accessories will instantly improve your technique, clean up your beads, and make every weld more predictable.

This blog post discusses the five accessories all great welders need for professional results without the professional price tag.

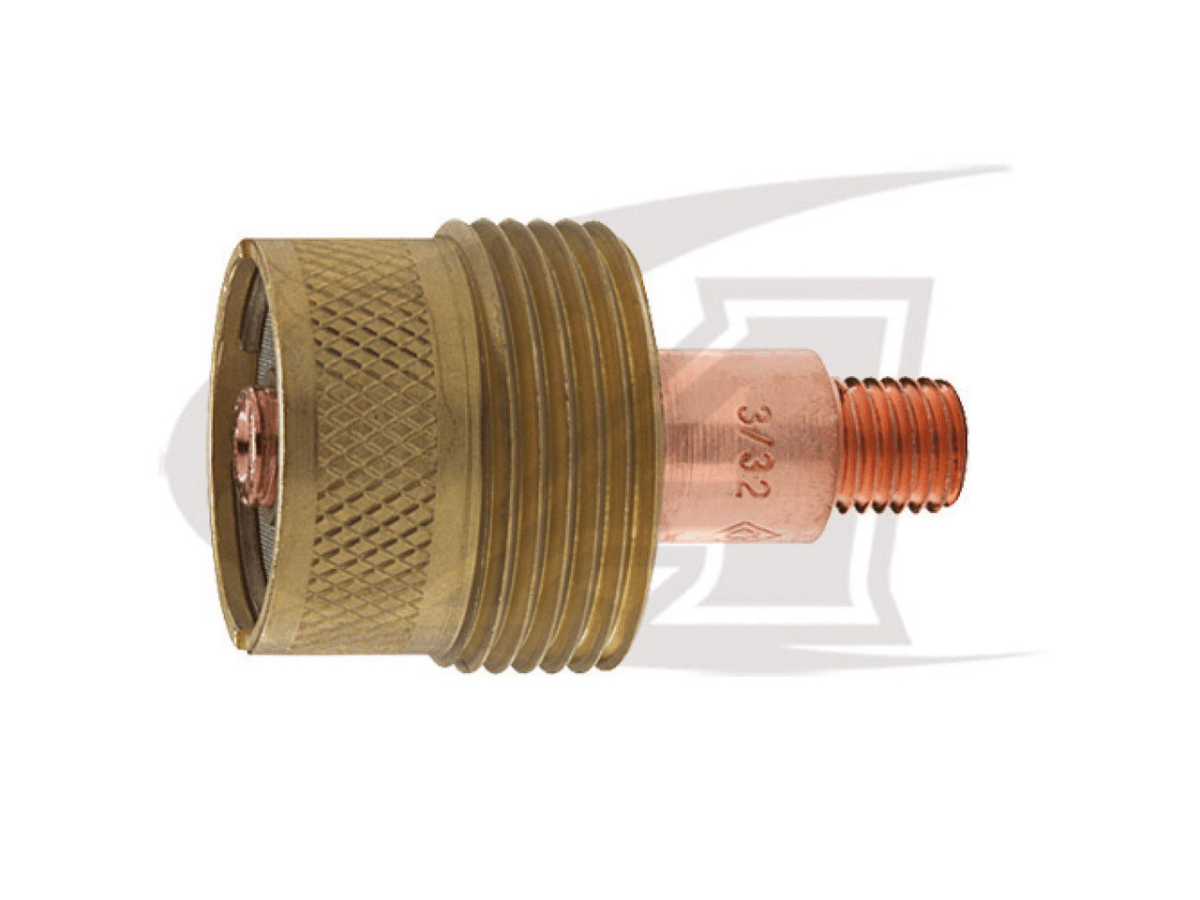

- Gas Lenses - Gas lenses significantly improve gas coverage over your weld pool, providing a smoother, more stable arc and superior shielding. This enhanced protection prevents atmospheric contamination, which leads to cleaner welds, reduced porosity, and less post-weld cleanup. It is especially critical for reactive metals like stainless steel and titanium. Replacing standard collet bodies or upgrading to Gas Lenses can make a world of difference.

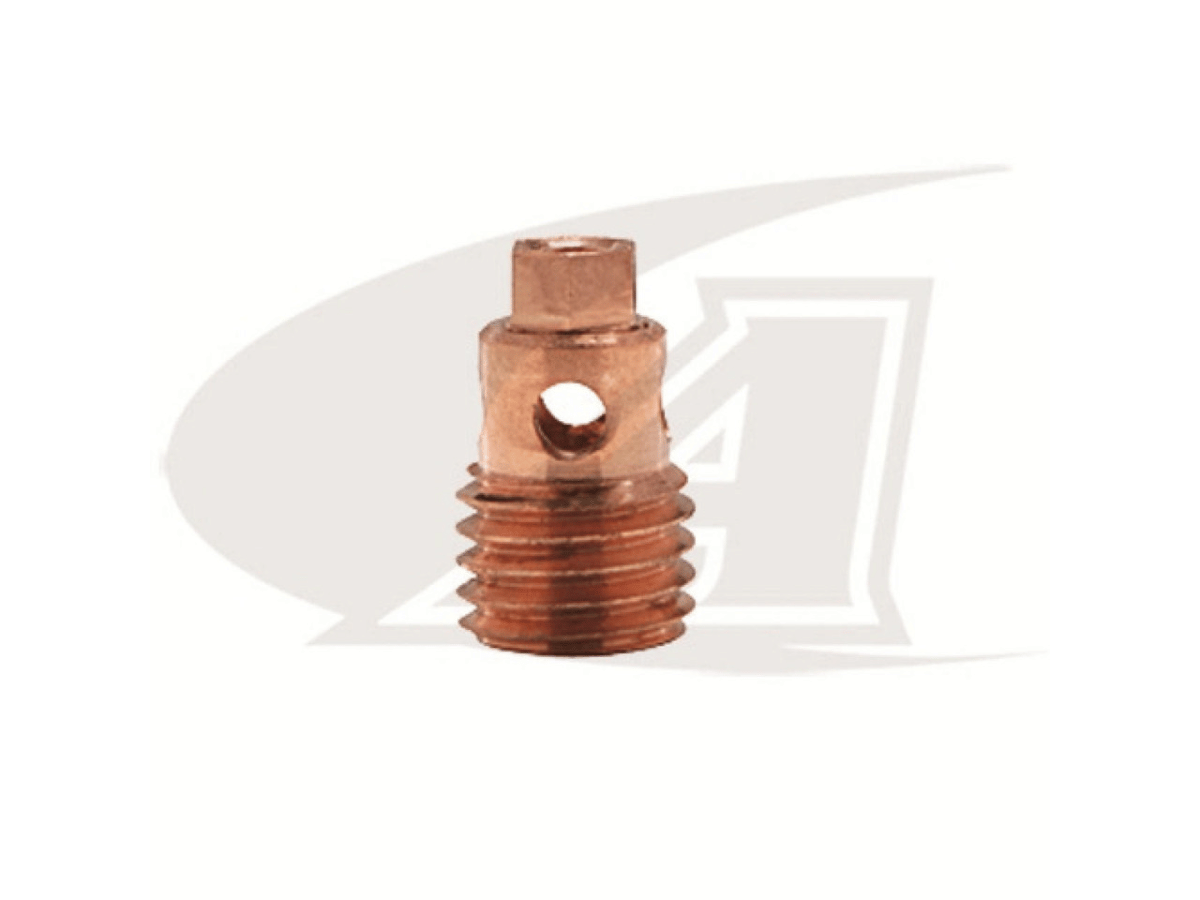

- Better Collets - Often overlooked, upgraded collet bodies offer a more consistent grip on your tungsten electrode. Replacing or upgrading to Wedge Collets ensures better electrical contact and heat dissipation, leading to improved arc stability and longer electrode life. A stable arc means more precise control and higher quality welds, reducing frustration and rework.

- The Right Cups and Nozzles - The cup or nozzle is crucial for directing the shielding gas precisely where it's needed. Using the correct size and type of cup (ceramic, Pyrex, or alumina) for your specific application — whether it's tight corners, heavy-duty work, or delicate thin material — ensures optimal gas coverage and visibility. The right choice prevents costly atmospheric contamination and helps achieve pristine bead appearance.

- Clean Filler Rod - Even with perfect technique, a dirty or contaminated filler rod can introduce impurities into your weld. Investing in high-quality, clean filler rod, and keeping it meticulously stored, is fundamental. It ensures the metallurgical integrity of your joint, preventing porosity, cracks, and discoloration, which are common issues with lesser quality or improperly handled materials.

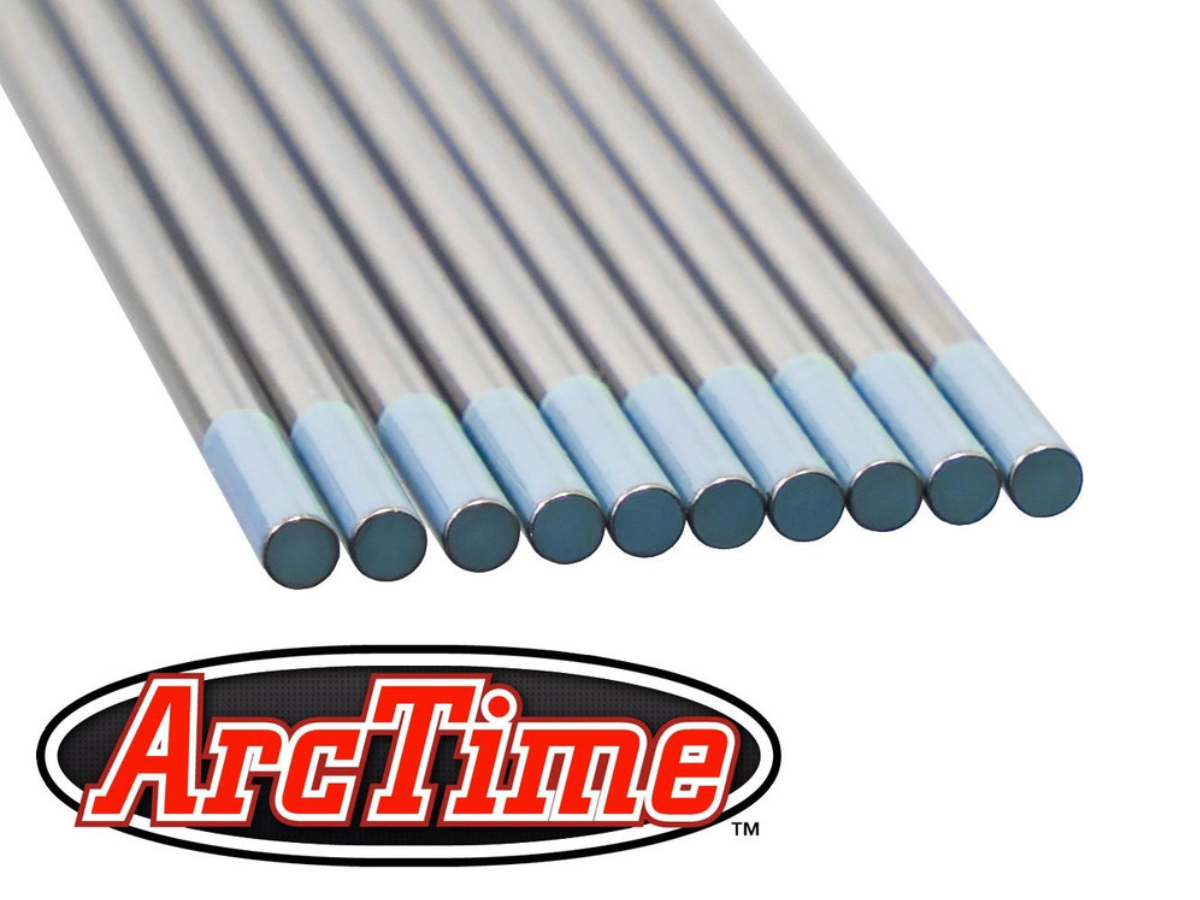

- Quality Tungsten - The tungsten electrode is the cornerstone of your TIG arc. Using high-quality tungsten, appropriate for your material and current type (AC/DC), ensures consistent arc starts, stability, and longevity. Premium tungsten resists "sugaring" and splitting, leading to fewer interruptions, smoother welding, and ultimately, a superior finished product.

|

Why Accessories Matter in Welding

Think of welding accessories like having the right tools for any job. Sure, you could change your oil with a butter knife, but why make things harder when you've got the right wrench?

A gas lens may appear to be just another component, but it can make your shielding gas ten times more effective. Instead of the chaotic, swirling gas flow you get with standard setups, a gas lens creates smooth, even coverage that wraps around your arc like a protective blanket. That means less oxidation, less spatter, and cleaner welds.

A good filler rod doesn't just melt differently; it helps your welds flow better and stay strong for years. When your accessories are working against you, you spend more time fighting your equipment than actually welding. However, when everything works together, you can focus on technique rather than troubleshooting problems.

Bottom line: Better accessories give you better control, and better control means better welds.

1. Gas Lenses: Get Better Gas Coverage Every Time

One of the easiest upgrades you can make to your TIG setup is swapping out your collet body for a gas lens. It's a small change, but the difference? Huge.

With a regular setup, your gas can swirl all over the place. That means poor shielding, and your welds suffer as a result. But a gas lens smooths it out. It sends your shielding gas in a calm, steady stream that wraps around your arc like a blanket. Less spatter, less oxidation, and cleaner welds.

You also get more reach. That smoother gas lets you stick your tungsten out further, which makes hitting tight spots and tricky angles way easier. Your arc stays stable, and your welds look sharper.

If you're welding stainless or aluminum, a gas lens is an essential accessory.

|

Large Gas Lens Collet Bodies .020" - 1/8" for 2 Series (9/20)

If you're ready to step things up, our Gas Saver Deluxe Pro Kit™ has everything you need in one box. It's packed with Wedge™ collets, clear Pyrex cups so you can see what you're doing, and ArcTime™ tungsten that lights up clean, every time. Available for 2 & 3 Series TIG rigs, check your torch type so you can just plug and play.

2. Better Collet Bodies: Keep Your Tungsten Where It Belongs

Standard collets work fine, if you're okay with "fine." But when you want real control, you need collets that actually do their job right. These little parts have two big jobs: hold your tungsten steady and make good electrical contact. When they're worn out or cheap, you get wobbly tungsten, sketchy arc starts, and hot spots that can fry your equipment.

|

Collet Bodies, .020" - 3/32" for 8 Series (WP-24) TIG Torches

Arc-Zone's TIG collet bodies are built to tighter specs with better materials. They grab your tungsten firmly and keep it there, while making sure the electrical connection stays solid. No more micro-movements that mess up your arc, no more inconsistent current flow.

When you pair good collet bodies with a gas lens system, everything works together like it's supposed to. For shops doing critical work where defects aren't an option, this small upgrade pays for itself in better first-pass rates and less rework.

Explore Arc-Zone's full range of collet bodies and gas lens options here.

3. The Right Cups and Nozzles: See Better, Weld Better

Using the wrong cup is like trying to thread a needle while wearing sunglasses; you're just making things harder on yourself. Cup choice isn't just about size (though that matters). It's about matching the right material and shape to what you're actually welding.

Ceramic cups are tough and handle heat well, perfect for heavy-duty work or long welding sessions. But when you need to see exactly what's happening in tight joints or complex shapes, clear Pyrex cups are the way to go. Being able to watch your puddle makes all the difference on precision work.

Working with titanium or other picky materials? Go bigger with #12, #14, or even #16 cups, which provide the gas coverage you need to keep everything clean. Need to get into tight spaces? Smaller cups let you maneuver while still protecting your weld.

Arc-Zone stocks every type you'd ever need. Their Monster™ Pro Kits handle heavy-duty applications with cups that have built-in screens for better gas flow. The Edge™ Pyrex Starter Packs give you crystal-clear visibility for detail work. And their high-purity flooding cups provide maximum protection when contamination absolutely can't happen.

The Monster™ series goes from #10 to #24, so whether you need massive coverage or compact access, there's a cup that fits your job perfectly.

Monster #24 = 1-1/2" (38.1mm) - Cup Only -

|

Explore Arc-Zone's full range of TIG welding cups here.

4. Clean Filler Rod: Your Weld Is Only As Good As Your Rod

Your filler rod becomes part of your finished weld, so using dirty, cheap, or wrong-spec rod is like building a house with rotten lumber. You might not see the problems right away, but they'll show up eventually, usually at the worst possible time.

Contaminated filler rod introduces porosity, cracking, and weak spots that can fail months or years down the road. In structural or aerospace work, that's not just embarrassing, it's dangerous. Good filler rod undergoes strict quality control and comes properly labeled and packaged to stay clean.

If your filler rod is off, even a little, your weld is going to pay for it. It doesn't matter how good you are if the metal you're feeding in isn't clean or consistent. Wiping down TIG Rod and the base metal is often overlooked, but can make a big difference.

|

ER316L - Stainless Steel TIG Welding Rod - 1lb. Pack

We carry rods for just about everything. Aluminum? We've got ER4043. Stainless? ER308L. Mild steel? ER70S-2. Even the specialty stuff like ERTi-5 for titanium and ERNiCrMo-4 for high-nickel jobs, we have those too.

And we're not talking mystery metal either. These rods meet AWS standards and mill certs are available upon request. . You get solid chemistry, smoother flow, and welds that hold.

Browse Arc-Zone's full filler rod catalog here.

5. Quality Tungsten: Don't Let Cheap Rod Mess With Your Arc

If your arc's dancing, won't light right, or keeps drifting, your tungsten might be the problem, not your technique.

We've all seen it: cheap tungsten that burns out fast or won't stay sharp. It makes you fight for every pass.

We stock the good stuff, 2% lanthanated, rare-earth blends, even thoriated if that's your go-to. Plus, pre-ground tips and micro sizes are available if you need precision.

When your tungsten's dialed in, everything runs smoother. Your arc listens. Your welds show it.

Different tungsten types work better for different jobs. 2% lanthanated is a solid all-around choice that works well across different amperages. Rare earth blends perform great at low amps. Thoriated tungsten is still used by many pros (just handle it safely). The key is matching your tungsten to your specific application.

Pre-ground tungsten takes the guesswork out of prep work. When your electrode is ground to the right angle and properly shaped, your arc starts clean and stays stable. No need for hand-grinding electrodes and hoping for the best for high production shops!

Arc-Zone stocks every major tungsten type, including their own ArcTime™ Hybrid and Amplify™ series. They offer pre-ground tips in both 20° and 45° angles, in every common size from .020" up to 1/4". For micro TIG work, their precision tips are ground to exact specifications.

Browse Arc-Zone's full tungsten electrode catalog here.

Arc-Zone® ArcTime™ Premium Hybrid Tungsten "One Tungsten, No Limits"

|

Final Thoughts

Welding comes down to controlling a number of variables all at once, and every one of these accessories helps you control something important. Gas lenses give you better shielding. Good collets improve arc starts and stability. The right cups let you see and protect your work with the proper amount of gas coverage. A clean filler rod ensures strong, reliable joints. High-quality tungsten ensures consistent arc performance.

You don't have to upgrade everything at once, but each little piece makes a real difference. Start with the biggest problem you're facing right now. Fighting gas coverage? Get a gas lens. Tungsten won't stay put? Better collet bodies. Can't see what you're doing? Try some clear cups.

Arc-Zone stocks professional-grade gear that actually works. Everything we sell has been tested and proven in real-world shops doing real work. When you're ready to stop fighting your equipment and start welding like a pro, Arc-Zone is here to get you what you need when you need it.