JWS-MDHPK

High-Purity Gas Solenoid Upgrade Kit for Miller® Diversion™ 165, 180 & Hobart® EZ-TIG 165i TIG Machines.

The JW Signature Series High-Purity Gas Supply Kit™ is an end-to-end gas supply upgrade kit from the regulator to the front panel of your machine.

We engineered it with high-quality stainless steel compression fittings, high density, non-permeable gas tubing and precision stainless steel gas solenoid.

The kit includes everything needed for the installation, and can be installed in minutes.

What Problem Does it Solve?The Gas Solenoid located under your TIG machines cover is "out of sight & out of mind".

The fact is, those solenoids are proven to leak shield gas and draw moisture and atmosphere contamination into your TIG torch! And because it's located "under the hood", you can't easily leak test the gas delivery path to verify the integrity of the system.

Why Does it Matter?Factory installed permeable rubber hoses, low-cost plastic gas solenoids and spring type hose clamps all lead to gas leaks, moisture and atmosphere contamination.

Kit Includes:

- High-purity gas solenoid with whip lead & blade connectors

- Stainless steel fittings and hose connectors

- High density, non-permeable gas supply hose

- Stainless Steel male 1/8” NPT to ¼” Compression

- Brass Male 1/8” NPT to 5/8” x 18 right hand female coupler

All components are made in U.S.A.

Installation Instructions:

Step #1.

Turn Off Machine's Power Switch and UNPLUG THE POWER CORD!

Step #2.

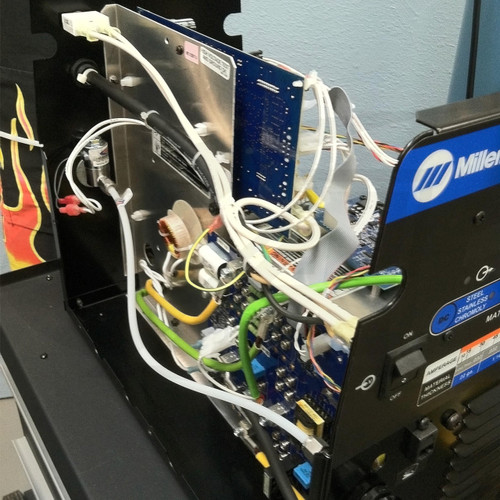

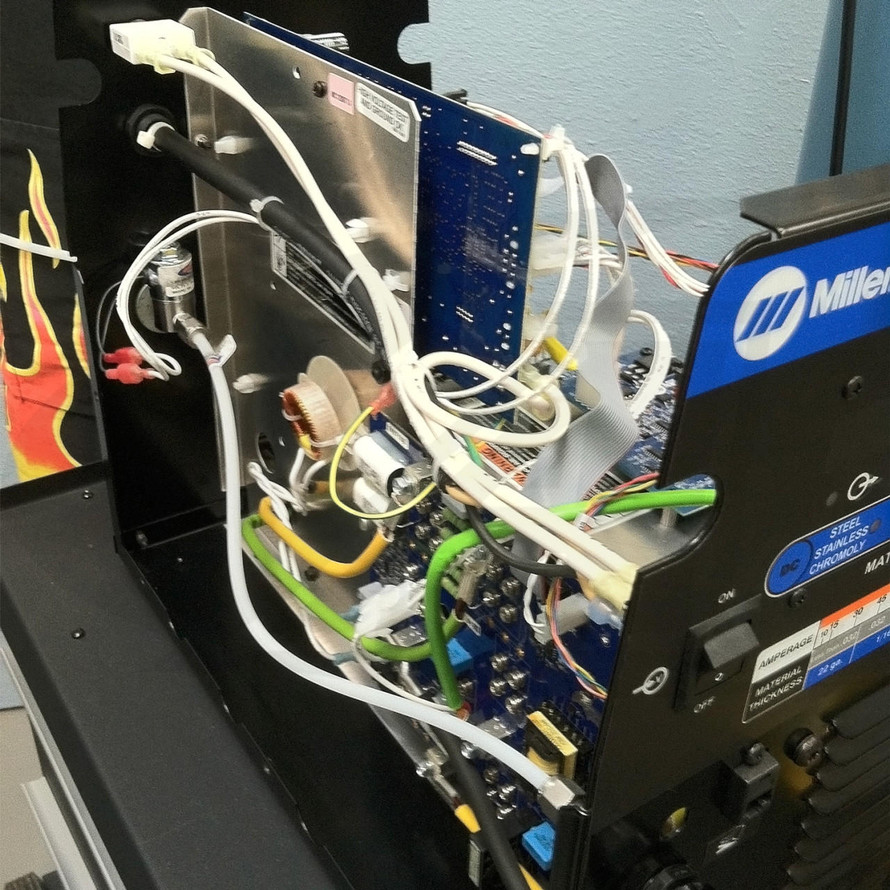

Remove the machine cover. Save the Mounting Hardware

Step #3.

Locate the 2 (two) solenoid power connectors. Unplug the power connectors and isolate them for Step #5

Step #4.

Slip the new solenoid whip lead into the chassis of the machine and direct it towards the existing gas solenoid power connectors.

Step #5.

Connect the whip lead blade connectors to the machine's solenoid power connectors.

Step #6.

Reinstall machine cover.

Step #7.

Mount the Arc-Zone high-purity solenoid the machine cover (using bulkhead fittings). Gently tighten gas supply hoses as needed.

Step #8.

Connect the Gas Supply line from the Flow Meter to the New external gas solenoid (do not over tighten)

NOTE:

The Kit includes two (2) Gas Hose Fitting types. You will need to determine which one mates to your Flow Meter Hose & TIG Torch Gas Connection.

Enjoy your High-Purity Upgrade Kit and good welding!

Want Even More Performance? Upgrade your Foot Pedal too!

Have a question? ask our team

(0) Reviews

(0) Reviews

There are no reviews associated with this product.

Write a Review