Controlled Purging for Immaculate, High-Quality Welds

Knowing how to control purge gas inside pipe and vessels is critical when welding stainless steel, titanium, and other oxygen-sensitive materials. Inflatable purge bags and baffles isolate the weld area, maintain consistent purge levels, and optimize internal weld quality.

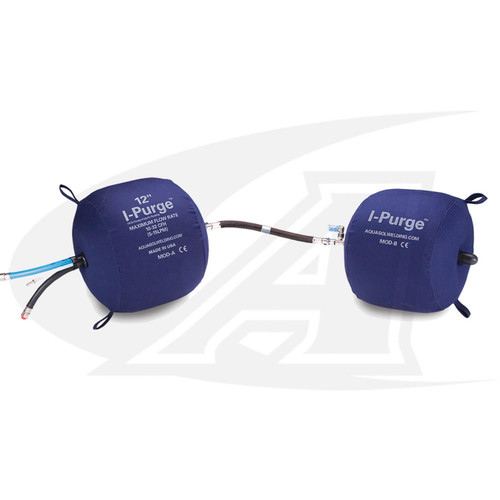

Purge bags and baffles are designed to improve purge efficiency while reducing gas usage and setup time. By limiting the purge volume to only the area being welded, these tools help lower argon consumption and eleiminate weld contamination.

Arc-Zone's purge solutions are engoneered for large pipeline systems, process piping, pressure vessels, and precision tube and pipe fabrication where internal weld quality and repeatability is mandatory. Multiple sizes and configurations are available to support every piping job and budget.

How Do Inflatable Purge Bags & Pull-Thru Baffles Improve Welding?

- Isolate the weld zone & maintain stable purge

- Eleiminate oxidation & internal discoloration

- Lower shielding gas usage & operating costs

- Speed up purge setup & improve repeatability

Designed for demanding welding environments, Perfected for over 25 years, Arc-Zone's purge products deliver consistent gas control and immaculate welds for your tube and pipe jobs.

Achieve perfect internal welds, reduce gas usage, lower labor and job turnaround costs with purge gas products developed by Arc-Zone and trusted by Pros for more than 25 years.