Consistent Wire Delivery for Reliable MIG Welding Performance

Knowing how to maintain smooth, consistent wire feed is essential for clean welds, stable arcs, and reduced downtime. Wire feeders and properly matched accessories play a critical role in MIG welding performance, especially when working with different wire types and materials.

At Arc-Zone.com®, we offer a complete selection of wire feeders, drive rolls, liners, gun adapter kits, and related accessories designed to support dependable wire delivery across a wide range of MIG welding applications. These components are selected for accuracy, durability, and compatibility in real shop environments.

Key components for dependable wire feeding

- Wire feeders for controlled, consistent wire speed

- Drive rolls designed to grip wire without slipping or deformation

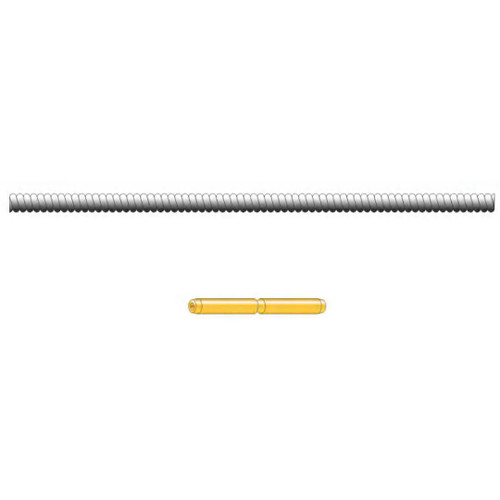

- MIG gun liners that provide a smooth, low-friction wire path

- Gun adapter kits to connect MIG guns to different feeder systems

- Replacement and upgrade accessories for maintenance and setup changes

Designed for common MIG welding materials

These wire feeding solutions are suitable for mild steel, stainless steel, and aluminum wire. Properly matching drive rolls, liners, and feeder settings to the wire type helps reduce burnbacks, bird-nesting, and inconsistent arc behavior.

How quality wire feeders and accessories improve results

- Maintain stable wire feed and arc performance

- Reduce wire slippage, drag, and feeding issues

- Improve weld appearance and penetration

- Minimize downtime caused by consumable wear

- Increase efficiency in production and fabrication work

Whether you’re replacing worn components, upgrading a MIG setup, or adapting equipment for a new application, the right wire feeding accessories help keep your welding operation running smoothly.

Keep your MIG welding system dialed in with wire feeders and accessories trusted by the pros.