Precision Purging Tools for Immaculate & Consistent Welds

Knowing how to eliminate oxygen during welding is critical when working with stainless steel, titanium, Inconel®, and other oxygen-sensitive alloys. Proper purge equipment helps create a clean weld environment, protect material integrity, and deliver immaculte, repeatable results.

Industries such as aerospace, pharmaceutical, medical device manufacturing, food processing, sanitary piping, and specialty vehicle fabrication require precise control of shielding gas. Atmospheric contamination must be eliminated throughout the entire purge system—from gas delivery to the weld zone.

Nuclear-grade approved purge solutions

Arc-Zone.com® is a global leader in precision TIG and PAW purging equipment. Our high-purity purge solutions are designed to deliver consistent oxygen-free weld zones, helping reduce gas usage, lower labor time, and improve overall weld quality and repeatability.

Complete Purge Equipment Solutions

- Precision oxygen sensors & monitors

- Water-soluble purge paper in sheets and pre-formed dams

- Ceramic & aluminum weld backing tapes

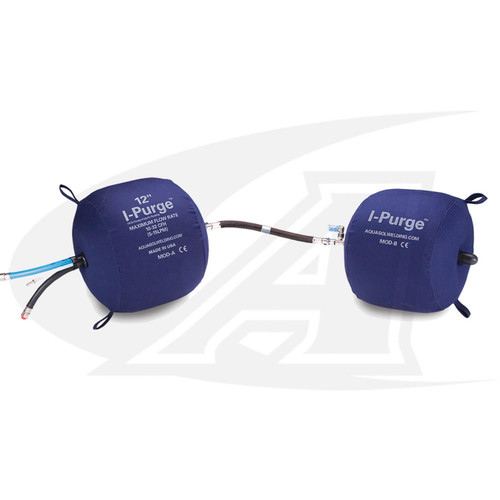

- Inflatable purge bags for tube & pipe

- Silicone baffle kits for controlled purge zones

- Purge chambers for enclosed welding environments

- TIG & PAW flooding cups and trail shields

- Silicone tube & pipe purge plugs

- Weld spacers, stainless steel & water-soluble

- Purge gas supply hoses, fittings & accessories

How Selecting Proper Purge Equipment Delivers Immaculate Welds

- Eliminates oxygen & moisture from the weld zone

- Maximizes weld appearance & internal bead quality

- Reduces rework, scrap & inspection failures

- Lowers shielding gas usage & labor costs

Arc-Zone Pro™ purge equipment is engineered to support clean, oxygen-free weld environments across a wide range of applications.

Control your purge process, protect weld quality, and improve efficiency with purge equipment trusted by the pros.